O-Matic Contruction 2.0

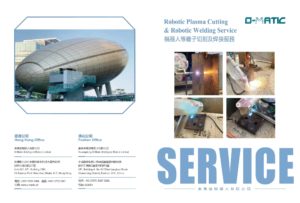

Robotic Plasma Cutting & Welding Capping Plate on Site

The idea is to enhance the cutting & welding method with O-Matic technology into the construction industry, the priority are cutting H-Beam pile & welding capping plate.

Robotic Plasma Cutting & Welding Capping Plate on Site has been adopted and completed over 300 nos. of H-pile in the public works project in 2021. Welding & cutting quality and productivity were significantly improved with the innovative robotic application.

Conventional cutting & welding vs. Robotic Plasma Cutting & Welding

1. Quality : Failure < 3%

High Quality – Surface cut edge and straight & flat level

High Quality – Surface cut edge and straight & flat level

2. Lower operation cost, higher productivity

3. Site Safety : Enhance construction site safety by eliminating the hazard (thermal and radiations) to the workers

Frequently Questions

Which party should consider to use this solution in the Project?

Main Contractor and subcontractor.

Do I need to buy the Robotic Plasma Cutting & Welding Equipment?

No. O-Matic’s professional services include:

- Robotic equipment

- Programme and design of welding procedure to suit project’s requirement

- Technical documentation

- Implementation of works

What is the requirement to facilitate the robotic plasma cutting & welding on site?

Robotic Plasmas Cutting

Electricity Supply : 380 V / 32 Amp., Min. 100 Amp

Air Flow (Air Compressor) : 5.2m3/min

Robotic Welding

Electricity Supply : 380 V / 32 Amp.

Mixed Shielding Gas : Argon/CO2

Can you provide the training to our staff?

Yes. O-matic shall provide the skill training to the Partners.

How long it take to review the feasibility of using innovative technology?

Please call our Project Team to conduct a site survey and provide us with the requirements of cutting pile and welding details for proposal and discussion.