O-Matic

O-Matic Intelligent Robot Limited

O-MATIC has over 20 years of experience from the US and Europe in automation machineries, manufacturing, ERP systems and software, R&D, injection moulding, sheet metal, electronics and robotics. The company has obtained patents on core manufacturing processes, and services such as prototyping, mechanical designs, QC specifications, certifications, and exports can be provided based on the needs of clients.

REC Green Technologies is the sole distributor for the following robotic products in Construction Innovation and Technology Fund’s pre-approved list :

Types

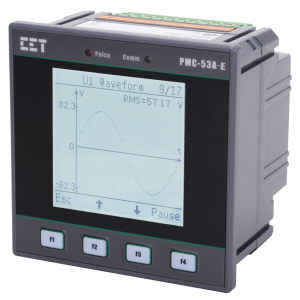

Constant Air Compressor (CITF Code: PA24-097)

Constant Air Compressor is a positive displacement, oil-injected twin-screw compressor that integrates the motor with the male rotor of the compressor for efficient operation. This design enables the compressor to operate quietly, making it ideal for construction sites and indoor environments, thereby reducing noise-related occupational health issues. The compressor features four swivel wheels at the base and four lifting rings at the top, facilitating easy transportation or lifting to work sites. All gauges, indicators, and control devices are centralized on a control panel, ensuring user-friendly operation. This compressor is built for long-term stable and reliable performance, making it a valuable asset in various applications.

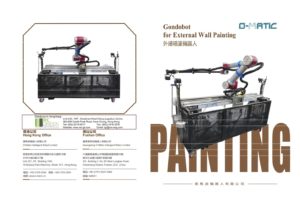

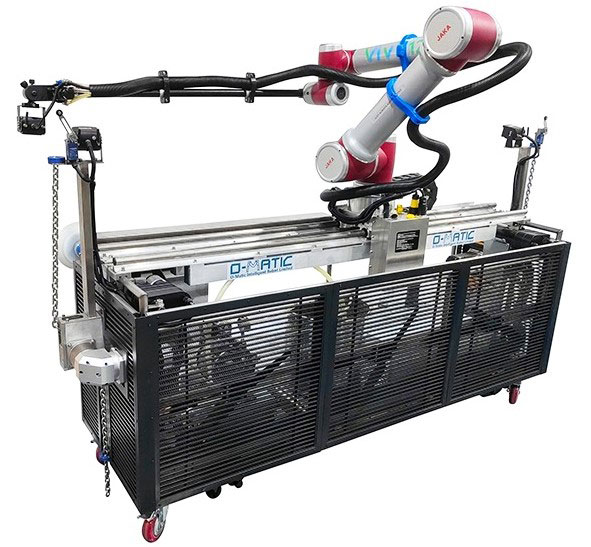

Gondobot (Painting)

Gondobot combines a collaborative robot, painting sprayer and gondola style robot to carry out the painting work at the external wall. It is not required painter to be on the robot and eliminate the risk of works having to work at heights.

Click here to download the product catalogue.

Gondobot (Watertightness Test)

Gondobot – The external wall spraying robot is a robot that is equipped with spraying equipment, push rod suction cups, and cameras and is designed to spray on building exterior walls. Programming allows it to independently position and spray the external walls of structures. Operators just need to regulate the robot’s general lifting with an industrial wireless remote control. Utilize a tablet to control the robot’s working program, and do remote spraying operations. The robot replaces operators’ high-altitude operations thereby enhancing the safety and quality of outside wall spraying.

Click here to download the product catalogue.

Transbot (CITF Code: PA19-011)

A wireless control battery-operated Unmanned Service Vehicle (USV) capable of carrying materials and tools in construction sites with different terrain conditions. Manual handling operations in delivery and unloading of heavy items can be performed by the Transbot. The robot can also increase work efficiency and reduce safety hazards.

Click here to download the product catalogue.

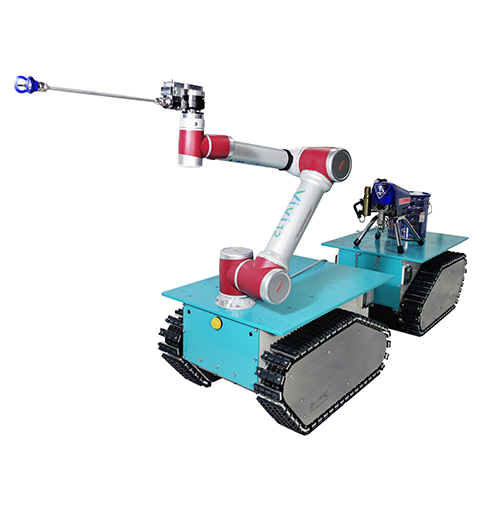

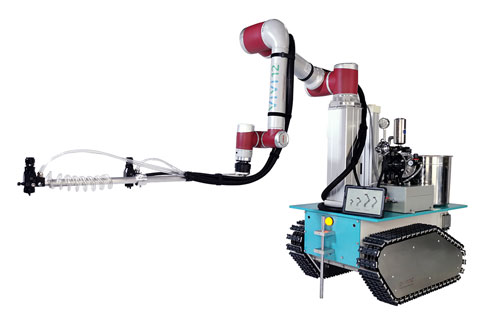

Water Spraying Robot (CITF Code: PA19-035)

The robot is suitable for indoor water testing. The test trajectory can be set according to the requirements of the site such that the robot can spray water according to it. With the built-in HD camera, the entire testing process can be monitored in realtime. Multiple robots can also be deployed at the same time.

Click here to download the product catalogue.

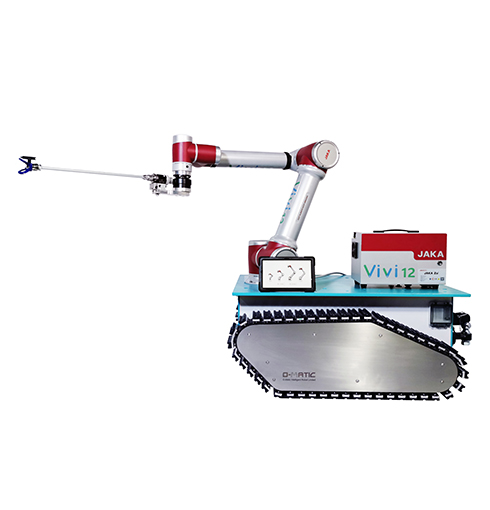

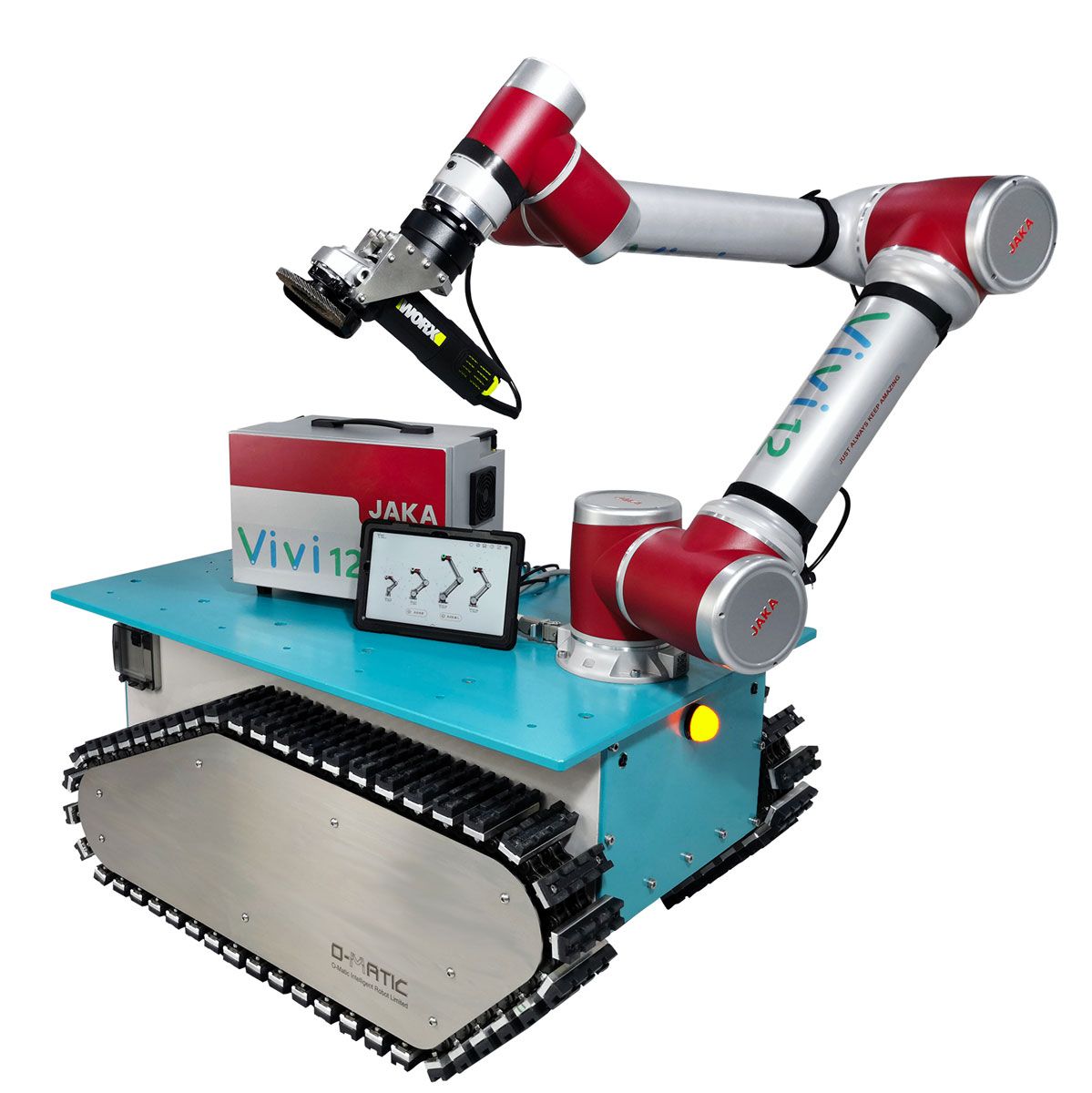

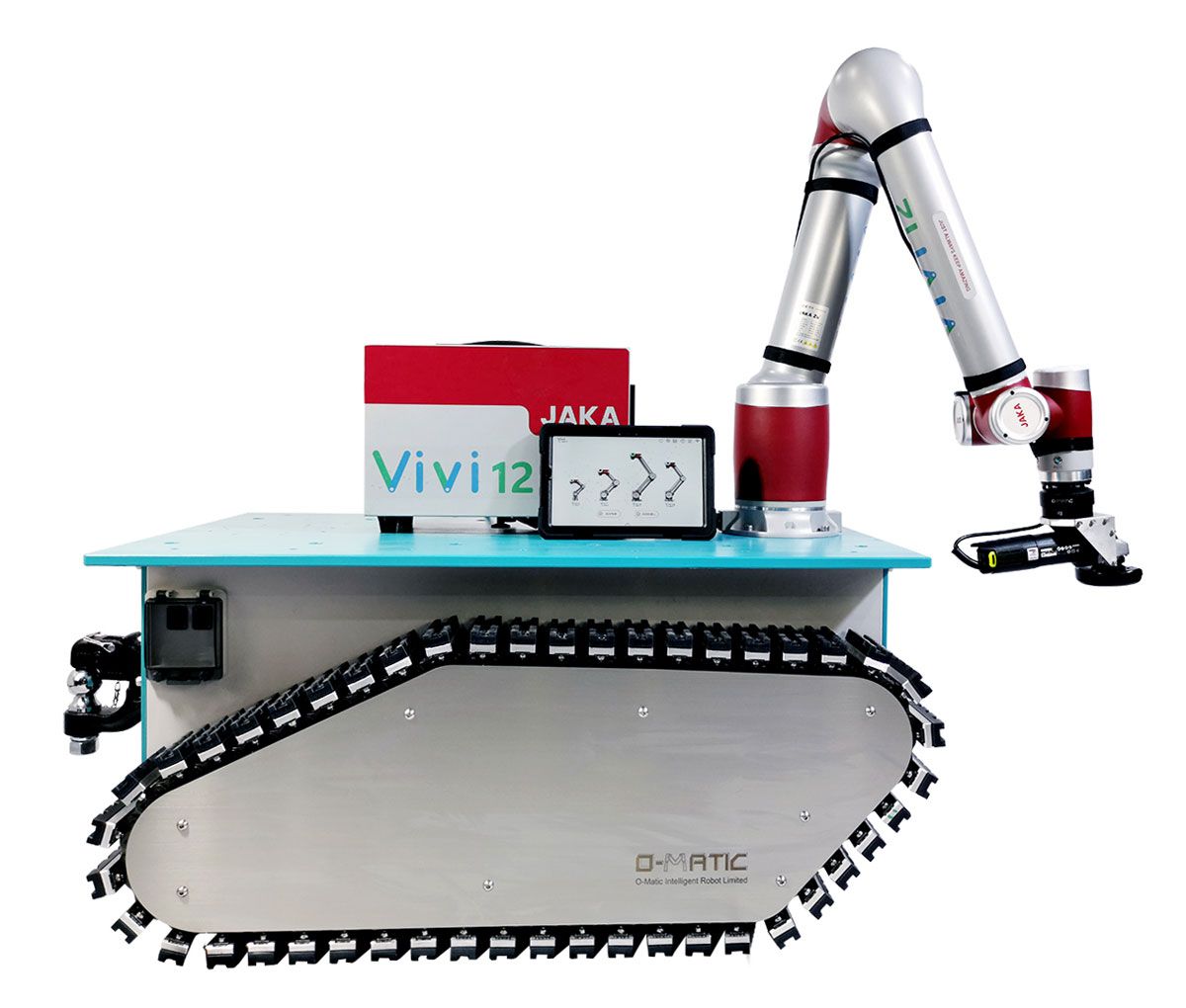

Drillbot (CITF Code: PA19-036)

A 6-Axis Collaborative Robot (Cobot) with a drilling tool attached to an Unmanned Service Vehicle (USV) that can maneuver in construction sites to handle drilling jobs.

Click here to download the product catalogue.

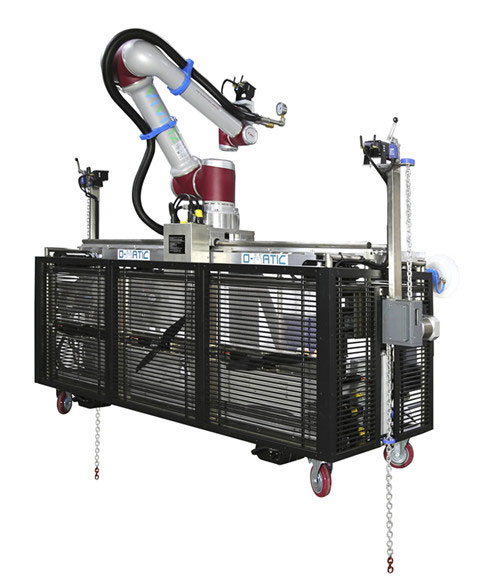

Mobile Welding Robot (CITF Code: PA19-037)

The robot is equipped with a mobile platform, welder and water cooler. It can maneuver in construction sites to handle welding jobs according to the programmed trajectory accurately.

Click here to download the product catalogue.

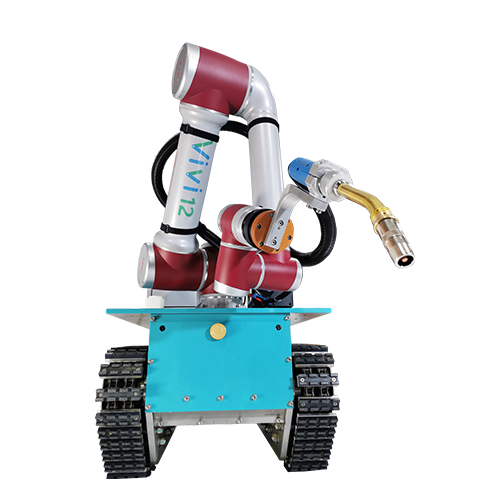

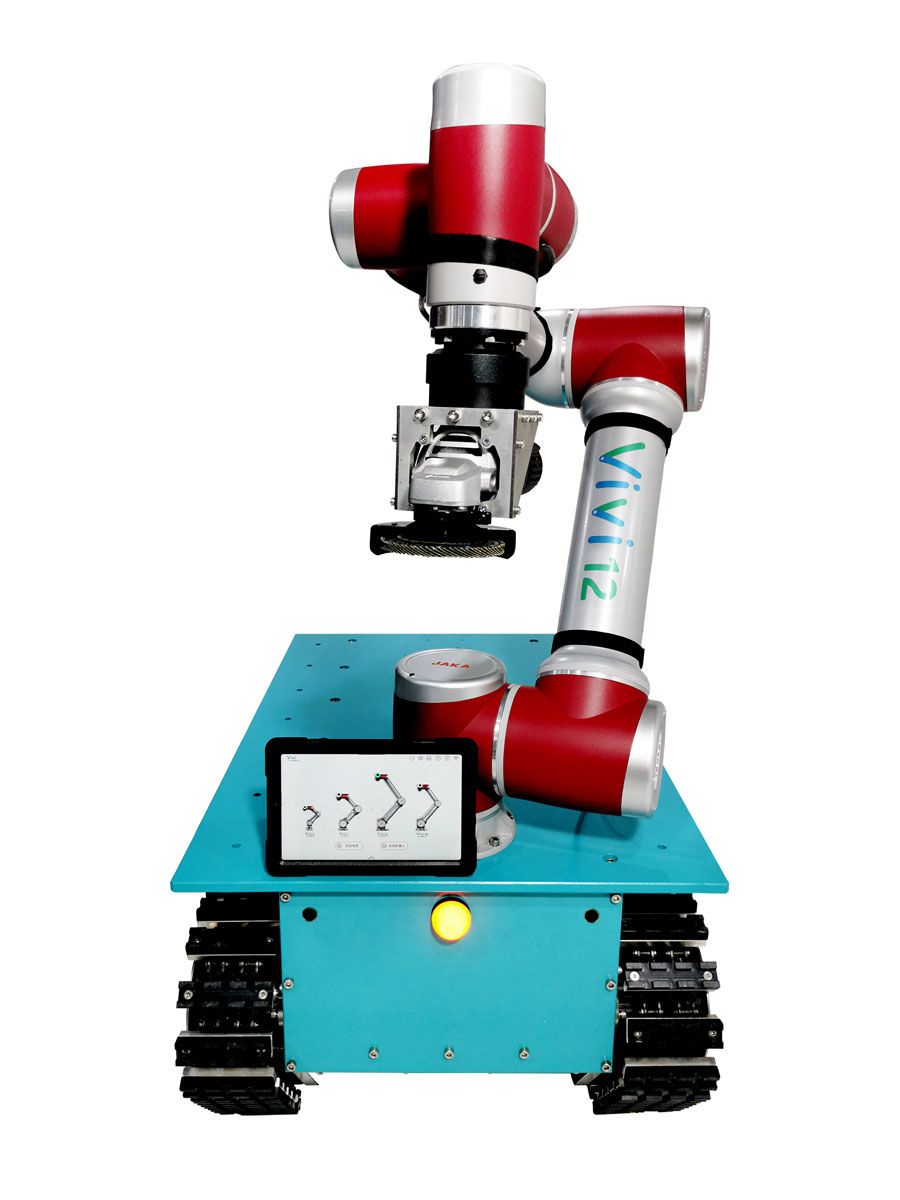

Paintbot (CITF Code: PA19-038)

A 6-Axis Collaborative Robot with a spraying tool attached to an Unmanned Service Vehicle (USV) that can maneuver in construction sites to handle painting jobs. With the use of Paintbot, workers are kept away from potentially harmful inhalants.

Paintbot Adjustable (CITF Code: PA22-004) – 1.5m Lifting Axis

The robot is a wireless control vehicle equipped with a cooperative manipulator, spray gun and lifting shaft. It is suitable for all kinds of painting jobs.

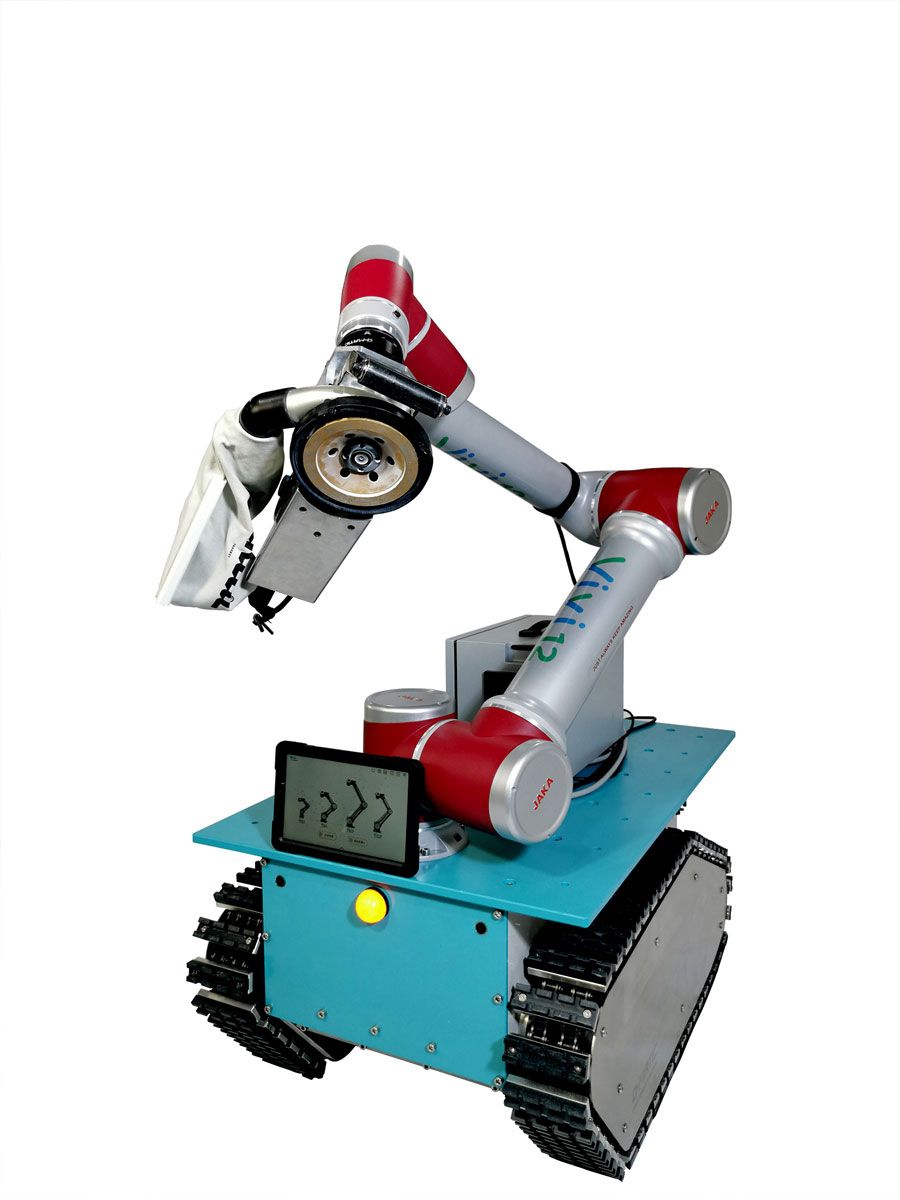

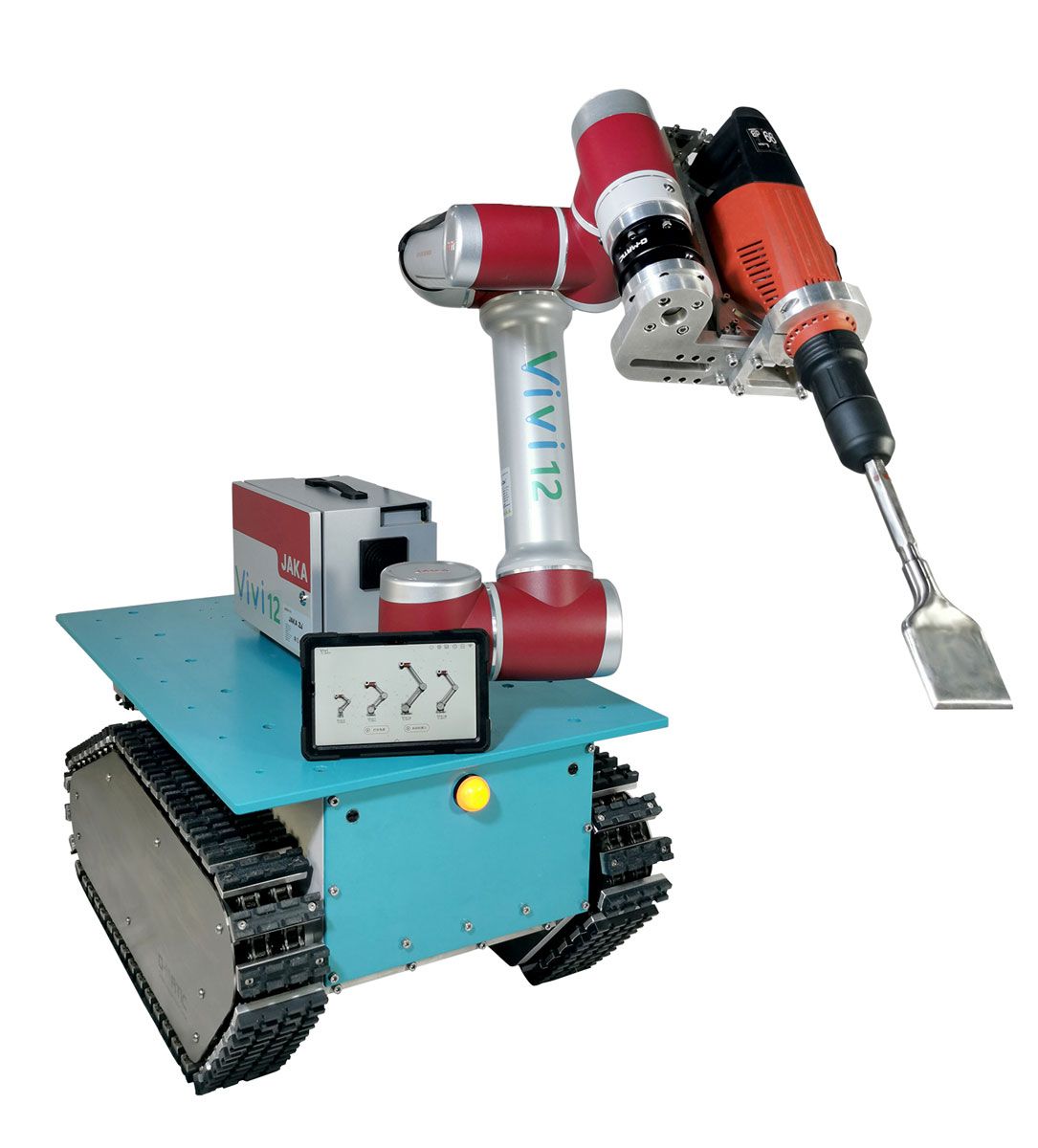

Floor Finishing Robot (CITF Code: PA24-008)

The floor Finishing Robot is a floor grinding robot equipped with a mobile robot platform (including a six-axis collaborative robot), a grinding disc and a vacuum equipment. It can be responsible for ground grinding work at construction sites. It can be operated using remote devices and is easy to operate.

Transbot 3 (CITF Code: PA21-035)

A wireless control battery-operated Unmanned Service Vehicle (USV) capable of carrying materials and tools in construction sites with different terrain conditions. Manual handling operations in delivery and unloading of heavy items can be performed by the Transbot. The robot can also increase work efficiency and reduce safety hazards.

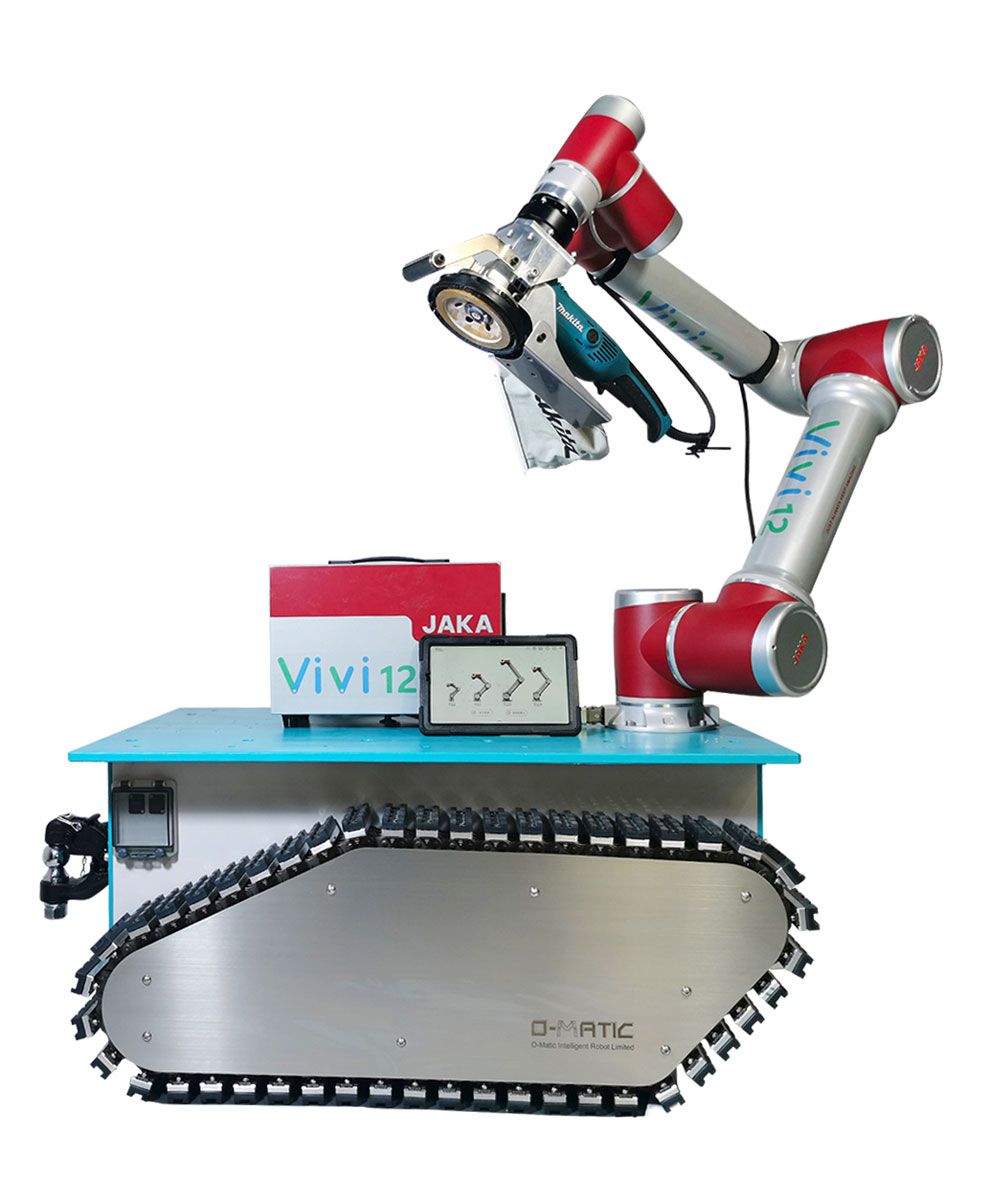

Grindbot (Edge Polishing)

A 6-Axis Collaborative Robot (Cobot) with a grinding tool attached to an Unmanned Service Vehicle (USV) that can maneuver in construction sites to handle grinding jobs.

Grindbot (Surface)

A 6-Axis Collaborative Robot (Cobot) with a grinding tool attached to an Unmanned Service Vehicle (USV) that can maneuver in construction sites to handle grinding jobs.

Jackbot (CITF Code: PA21-043)

A 6-Axis Collaborative Robot (Cobot) with a jack hammer attached to an Unmanned Service Vehicle (USV) that can maneuver in construction sites to handle spalling jobs.